TAKE THE FULL CONTROL

OF YOUR WAREHOUSE

Revolutionize your warehouse operations step-by-step

say goodbye to fulfilment

errors

lost packages and

insufficient charges

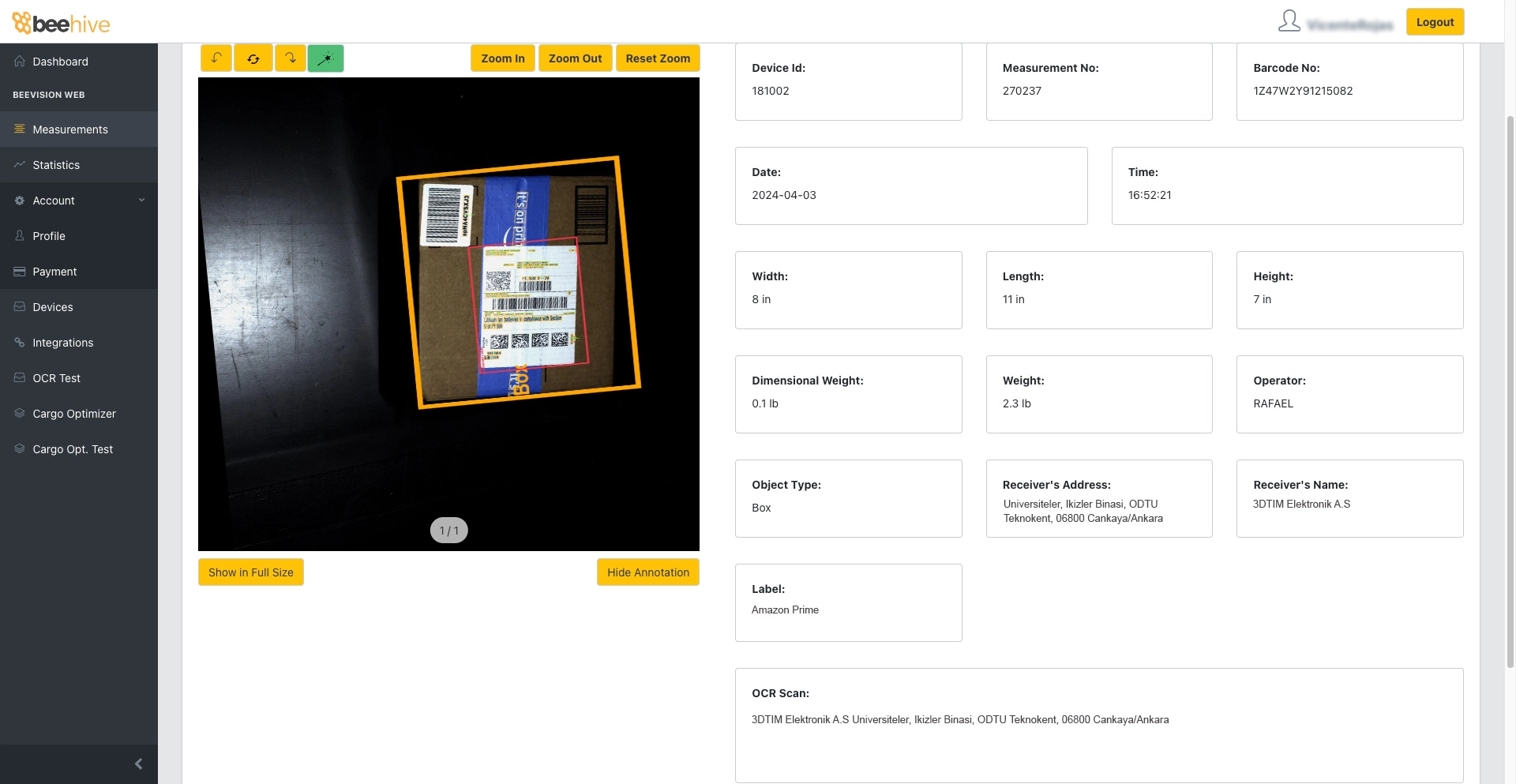

Integrate automation components with BeeHive, collect and analyze operation data and have error-free warehouse automation.

RETENTION TIME

SUBSCRIPTION

RESEND AT ONCE