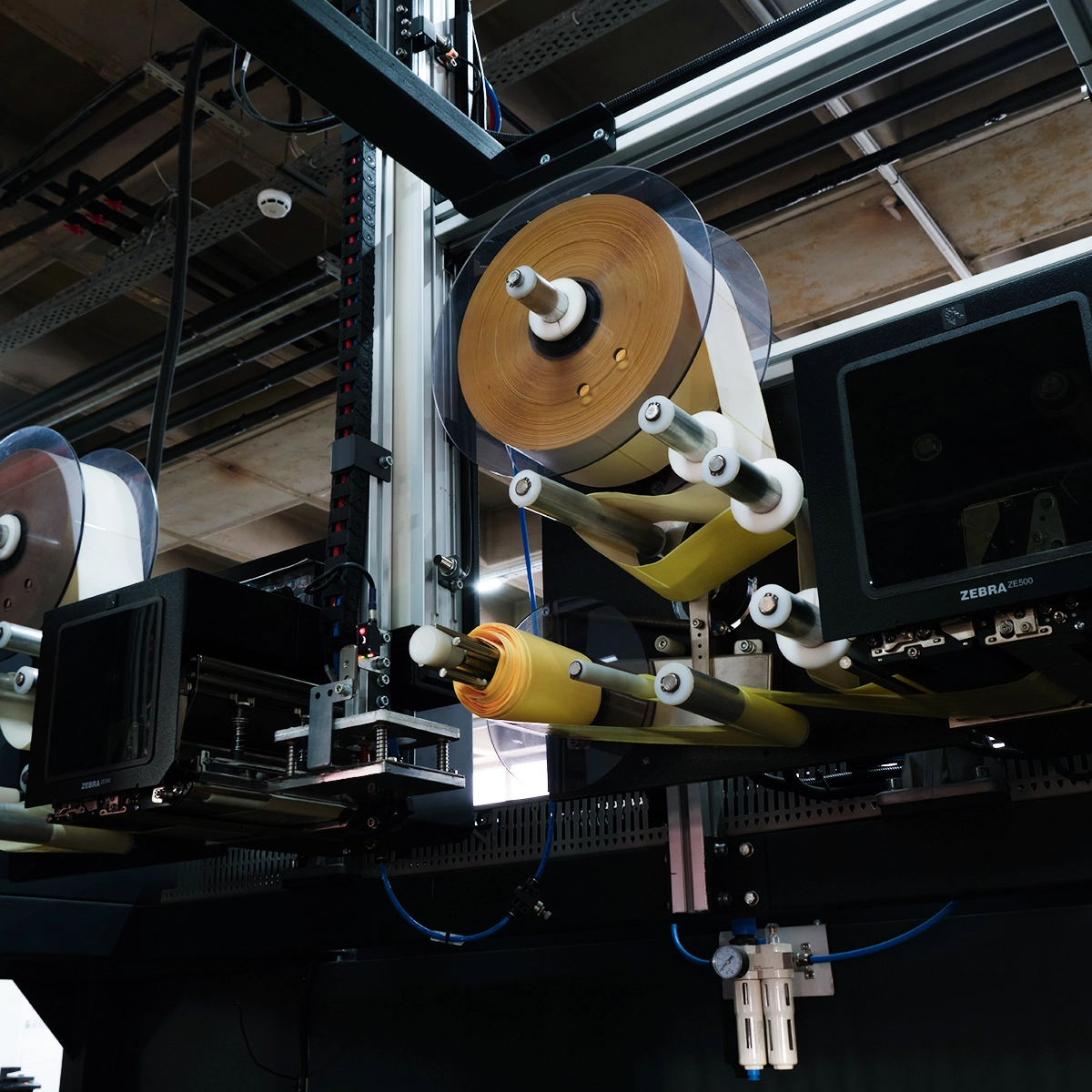

BeeVision 400 Automatic Label Applicator: High-Throughput Labeling System

BeeVision 400 Automatic Label Applicator is a high-throughput, industrial-grade label printing and applying

system designed to bring fast, accurate, and fully automated labeling to warehouse, logistics, and parcel

handling operations. As a comprehensive turnkey solution, it harmonizes hardware and software in seamless

integration with other BeeVision products to maximize efficiency and throughput.

Equipped with support for thermal label printing, BeeVision 400 eliminates the need for ribbons, reducing

consumable costs and operational waste while speeding up processes. The system is optimized for a wide range

of label sizes and features easy label slot swapping through an innovative mechanical design that lets a

single operator change rolls without tools.

BeeVision 400 automatically applies labels onto envelopes, bags, and parcels of different heights — from

small e-commerce shipments to larger packages — with versatile object handling from 10 × 10 × 0 cm up to 80

× 80 × 60 cm. Each printer can apply up to 1500 labels per hour, and multi-printer configurations raise

total throughput to up to 3000+ labels per hour, making it ideal for high-volume logistics environments.

A built-in label verification feature uses the BeeVision 200 Barcode Reader to automatically scan and verify

each applied label during output, ensuring that labels are correctly placed and readable before packages

continue in the workflow. This improves traceability, reduces mis-shipments, and minimizes manual checks.

BeeVision 400 works out of the box with "Plug & Measure" simplicity, requiring minimal setup time for rapid

deployment. It integrates seamlessly with other systems — including BeeVision 190 dimensioners, BeeSort

sorting lines, and the BeeHive warehouse automation management platform — enabling web service API

connectivity for automated label data and workflow control.

BeeVision 400 Automatic Label Applicator is a future-ready labeling solution that brings speed, accuracy,

and automation to modern parcel handling, helping logistics teams reduce manual labor, eliminate errors, and

achieve significant productivity gains.